Non-destructive testing

Higher, faster, cheaper and further… That applies not only to development of airplanes, but in the figurative sense also to many other technological areas. Tough, light and reliable materials are the key for many of developments. Identification of defects, impurities or cracks in these materials is therefore important. X-ray imaging is a tool used for these purposes for a long time. However, the standard imaging technology was tuned mostly for metals. Therefore, the traditional X-ray imaging systems fail in case of modern light materials such as composites. The novel materials therefore call for novel inspection technologies and photon counting detectors are ideal for this purpose.

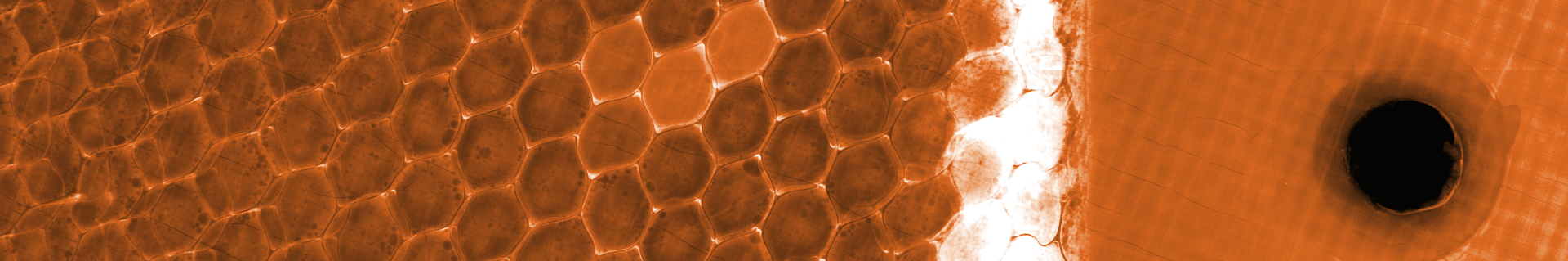

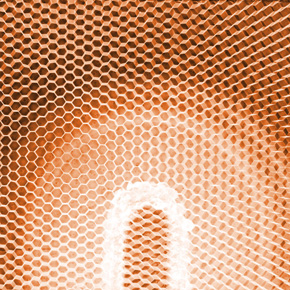

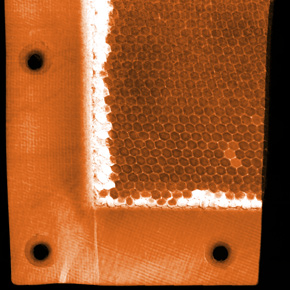

Similarly as it was in the case of applications in biology, also here the non-destructive testing (NDT) takes advantage of the sensitivity to low energies. Therefore, light materials such as carbon fibers, epoxies, etc. are easily revealed in a great detail. Combining the sensitivity to low X-ray energy photons with the very high dynamic range of photon counting detectors creates a powerful tool for NDT in airspace industry and elsewhere.

The following examples of composite material X-ray images were provided with courtesy of IEAP-CTU in Prague.